Main

· Science

· Instrument

· Backend

· Channelizer

· Correlator

· Receiver

· Optics

» Data Acquisition

· Local Oscillator

· Base

· Site

· Analysis

· Results

· Publications

· Team

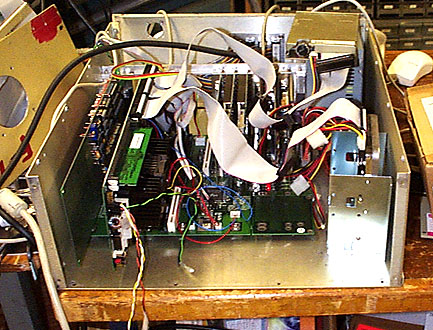

An exploded view of the data acquisition computer. The final version will have hard drives in pressure housings.

The MINT data acquisition system and telescope control represent a major departure from traditional instrument systems in that it uses as many pre-packaged systems as possible. The usual tendency is to design a proprietary software package around either a real time operating system or other paired-down system. The user interfaces with the hardware at register level, often programming in C or other low-level language. The success of the MAP beam mapping system and the MAT/TOCO SIS tuning rig along with many other complicated systems encouraged us to organize the control and acquisition around LabView.

Labview offers a very short software learning curve coupled with a large array of industry standard hardware interface cards. In addition, most manufacturers develop LabView libraries for their instruments. The tradeoff is that LabView is a higher-level interpreted programming language, so there is considerably more overhead in computing resources. In the era of Moore's Law, processor power is easy to come by. MINT has two PII class SBC computers, one for data acquisition and one for telescope control. Both run Windows 2000, perhaps the first relatively stable operating system from Microsoft. All input and output is handled through either computer I/O ports, or National Instruments Cards, with the exception of the data telemetry, which goes out on a bi-phase card adapted from the ballooning payloads. The Correlator data comes in on two high speed DIO cards, the correlator control goes out on low speed I/O cards. All analog housekeeping signals are pre-processed via filter and bias cards, then sampled by 2 64 channel 16-bit A/D cards. The base is controlled via serial interface to the motor controllers.