Main

· Science

· Instrument

· Backend

· Channelizer

· Design

» Enclosure

· Fabrication

· Performance

· Future Revisions

· Correlator

· Receiver

· Optics

· Data Acquisition

· Local Oscillator

· Base

· Site

· Analysis

· Results

· Publications

· Team

The enclosure is a critical element of every microwave device. The primary function of our enclosure is to shield the rest of the telescope from rfi. It serves as a method to hold the circuit flat against a solid case ground. It is also used to isolate individual components on the circuit from each other.

The design for the enclosure must be considered during the design of the circuit. There are ground strips between different parts of the channelizer that connect directly to "walls" in the enclosure. The Circuit board is sandwiched between the lid and the box.

Both the lid and the box are made from solid pieces of aluminum. They are hogged out on a CNC mill. The intricate patterns on the lid would be impossible to mill by hand. The box bottom is milled to .1" to allow the bottom shape to deform and be defined by the lid. This ensures a solid ground contact.

The critical dimensions on the enclosure are the separation of the circuit elements from the walls and from the top. Both tend to lower the impedance of transmission lines. Gupta et al. report that a height of top vs. substrate height of 5 gives negligible effects. For our design, this ratio is about 25.

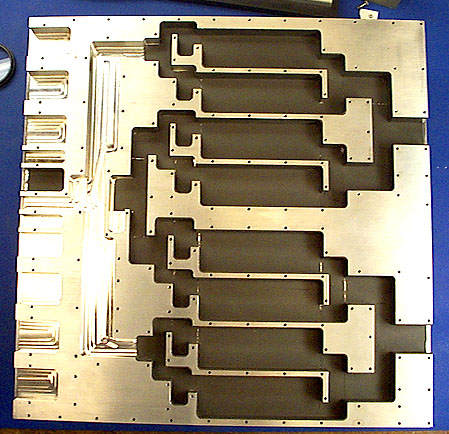

fig. 1 Top view of the enclosure lid

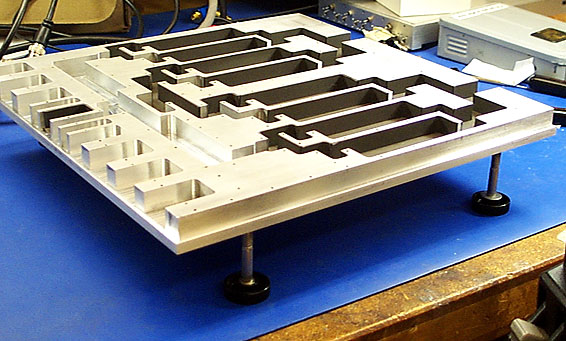

fig. 2 side view of the lid. The lid is sitting on knobs which are used for handling

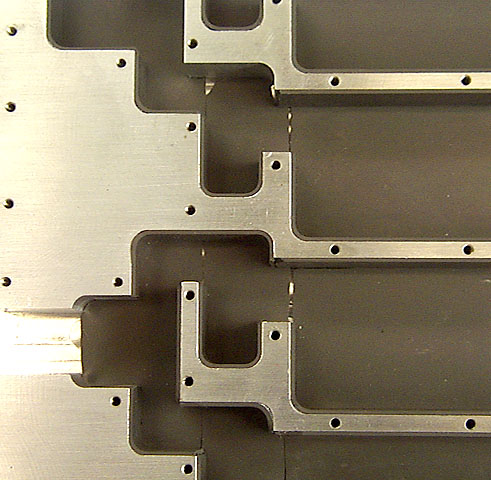

fig. 3 magnified view of the lid showing the eccosorb lining.

There is one problem with designing small channels and cavities in the lid: resonances. The resonant frequency can be modeled, but it is usually difficult to do this reliably. To suppress the cavity resonances, all the walls are painstakingly covered if ecosorb, a microwave absorbing material. The ecosorb comes in many different forms, the type we use comes in rubber mats with sticky tape on one side.